-

Tel/Wechat/Whatsapp +86 13926285591

-

Email hanke@opeetv.com

-

Tel/Wechat/Whatsapp +86 13926285591

-

Email hanke@opeetv.com

What Is LCD Panel Grade in LCD TVs and Monitors?

LCD panel grade is an industry term commonly used in TV and monitor manufacturing to describe the visual quality level of an LCD panel. Unlike specifications such as resolution or brightness, panel grade does not refer to performance, but to tolerance limits for pixel defects and other visual imperfections.

In OEM and bulk production, LCD panels are usually classified as A+, A, or A−(Q), based primarily on the number and type of pixel defects, such as bright pixels or dark pixels, observed during inspection. These grades help manufacturers and buyers agree on acceptable quality levels before mass production begins.

It is important to note that there is no single global standard for LCD panel grading. Criteria may vary slightly between manufacturers and panel suppliers(BOE, CSOT, HKC, INNOLUX, etc). In this article, we explain how LCD panel grades are defined in practice, what A+, A, and A− really mean, and why panel grade is an important factor when specifying LCD panels for TVs and monitors.

In particular, the grading examples and explanations in this article reference BOE’s panel standards. Based on our long term experience as a TV manufacturer, BOE LCD panels are our default choice for mass production, as their grading criteria are widely recognized in the industry and offer more consistent quality control and long term stability across production batches.

What Does “LCD Panel Grade” Mean?

LCD panel grade refers to the classification of an LCD panel based on its pixel defect tolerance and overall visual quality, rather than its electrical or optical performance specifications.

In simple terms, panel grade does not describe whether a panel is “good” or “bad”. Instead, it defines the acceptable range of visual imperfections that may exist on a panel while still meeting production and delivery requirements.

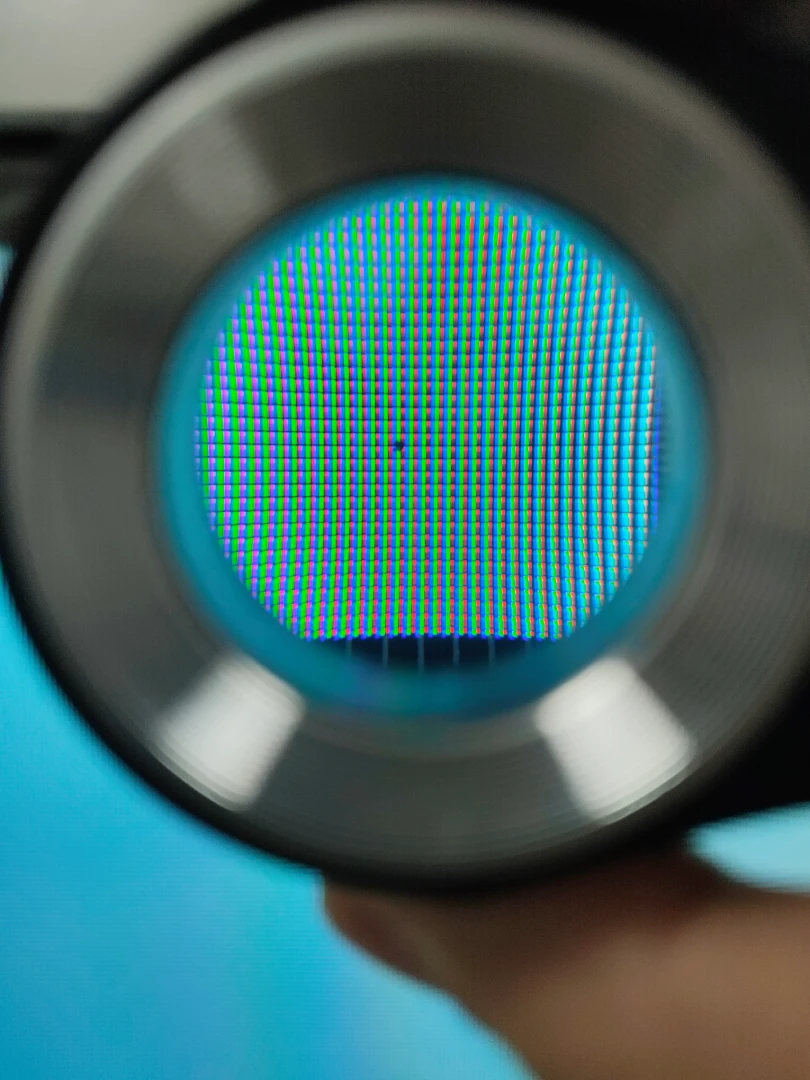

Below is a magnified inspection image of an LCD panel, showing normal operation of individual pixels. Under commonly used industry grading criteria, a panel with no visible pixel defects is generally considered to meet A+ grade requirements.

RGB

3 sub-pixel units in total.In the LCD industry, panel grading is largely determined at the pixel and sub pixel level, as each pixel is composed of red, green, and blue sub pixel units that must operate correctly to display accurate images. Defects at this level, such as bright pixels, dark pixels, or stuck sub pixels, form a major basis for panel grade classification.

At the same time, panel grade is not defined solely by pixel behavior. Certain visual issues may be related to manufacturing or handling processes, such as dust particles trapped inside the panel or minor surface contamination, rather than actual pixel damage. Different manufacturers may apply slightly different criteria when distinguishing between pixel related defects and process related imperfections. In the following sections, we provide practical examples to illustrate how these factors are evaluated in panel grading.

Concept: Major Defects

This classification follows panel supplier specifications commonly used in the industry, including BOE standards. Visual defects are divided into major defects and minor defects for quality evaluation.

A major defect is a defect likely to result in functional failure or significantly reduce the product’s usability for its intended purpose.

PLEASE NOTE: Panels with major defects are considered unacceptable and are excluded from panel grading. Such panels do not fall within A+, A, or A− classifications. As a result, this article will not go very deeply into the major defects part.

Major Defect Type (NO GRADE!) |

|

|---|---|

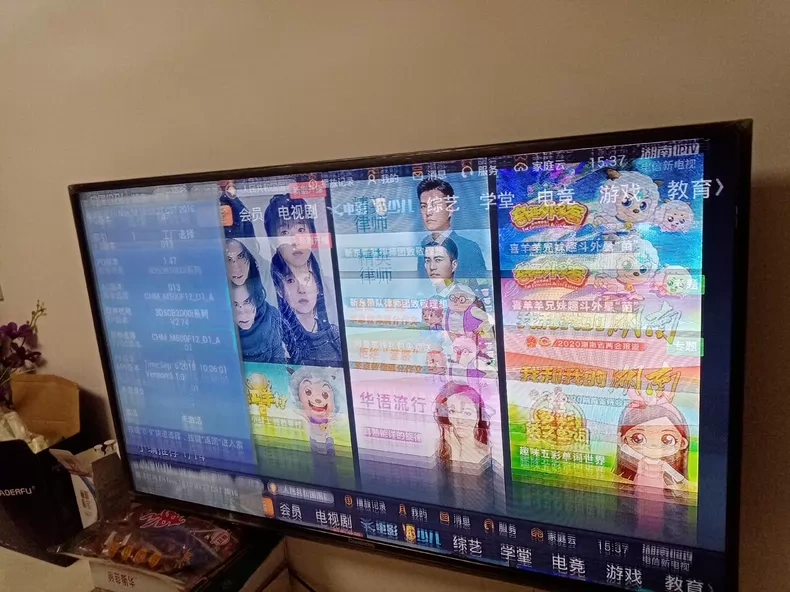

| Vertical Line | An abnormal line appears in the vertical direction. |

| Horizontal Line | An abnormal line appears in the horizontal direction. |

| Cross Line | Abnormal intersecting lines (cross lines) appear on the display. |

| No Display | The screen fails to output any signal or image. |

| Irregular Display | The displayed image shows signal interference or distortion. |

General Causes And Potential Solutions of Major Defects

1. COF Bonding Issues

COF bonding defects are a common cause of major defects in LCD panels. The COF, commonly referred to in the industry as TAB, connects the LCD glass to the driving circuitry through fine bonding pads. If the bonding alignment is incorrect or if bonding strength is insufficient, it may result in line defects, signal loss, or complete functional failure.

In addition, COF bonding areas are highly sensitive to contamination. Dust particles, moisture, or other foreign substances on the bonding pads may interfere with electrical contact, leading to unstable signals, short circuits, or progressive degradation over time.

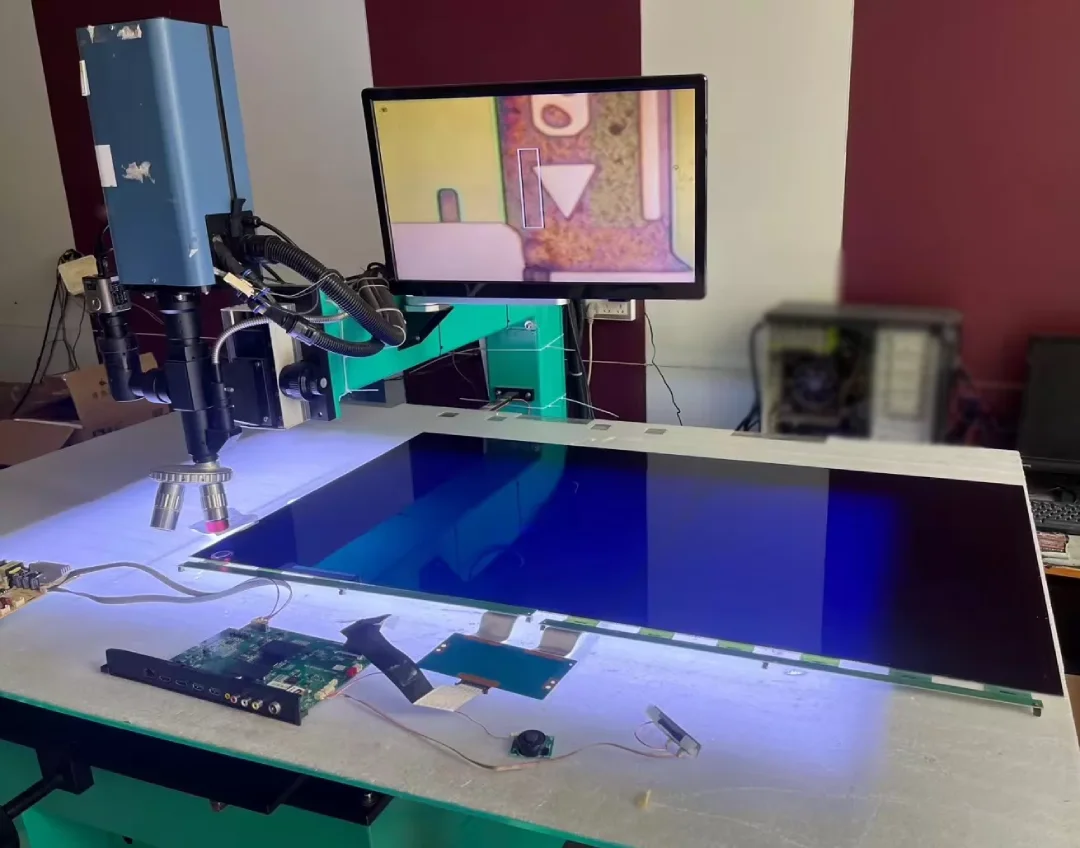

In many cases, TAB related defects can be corrected by replacing the COF using a bonding machine. The magnified image below illustrates the bonding area, where precise alignment of bonding pins is required to ensure reliable electrical connections.

Additional Knowledge: In earlier panel designs, COF connections were often located on the side of the panel. In newer panel structures, COF bonding is commonly positioned at the bottom of the panel. When a wet cloth is used to clean the screen surface, gravity may cause liquid to flow downward and reach the COF area. If moisture enters the bonding region, it may contaminate the contacts or cause short circuits, potentially resulting in panel malfunction or permanent damage.

COF Bonding Solution(Industry)

In manufacturing and repair processes, certain COF bonding defects can be addressed using specialized equipment such as bonding machines or laser wire repair systems. These solutions are typically applied to correct alignment issues, restore electrical connections, or replace contaminated COF components when conditions allow.

However, COF bonding solutions involve complex process control, equipment calibration, and operator experience, and are therefore considered a specialized technical topic. For this reason, detailed discussion of COF bonding repair methods is beyond the scope of this article. If there is interest, we can provide a separate technical note dedicated specifically to COF bonding processes and solutions. In addition, we are selling these machines to the Indian market to help our clients fix their open-cell. If you are willing to get one, please contact us.

2. Driver Related Issues

Driver issues refer to abnormalities in the source driver or gate driver circuitry that control pixel addressing and signal output. Failures in driver components or connections may cause severe display defects, such as missing lines or unstable image output, and are therefore classified as major defects.

Concept: Minor Defects

A minor defect is a defect that does not reduce the usability of the product for its intended purpose. As long as minor defects remain within defined tolerance limits, the LCD product can still be used under normal application conditions. The primary impact of minor defects is that the panel is classified into different grade levels according to industry grading criteria.

Minor Defect Type | |

|---|---|

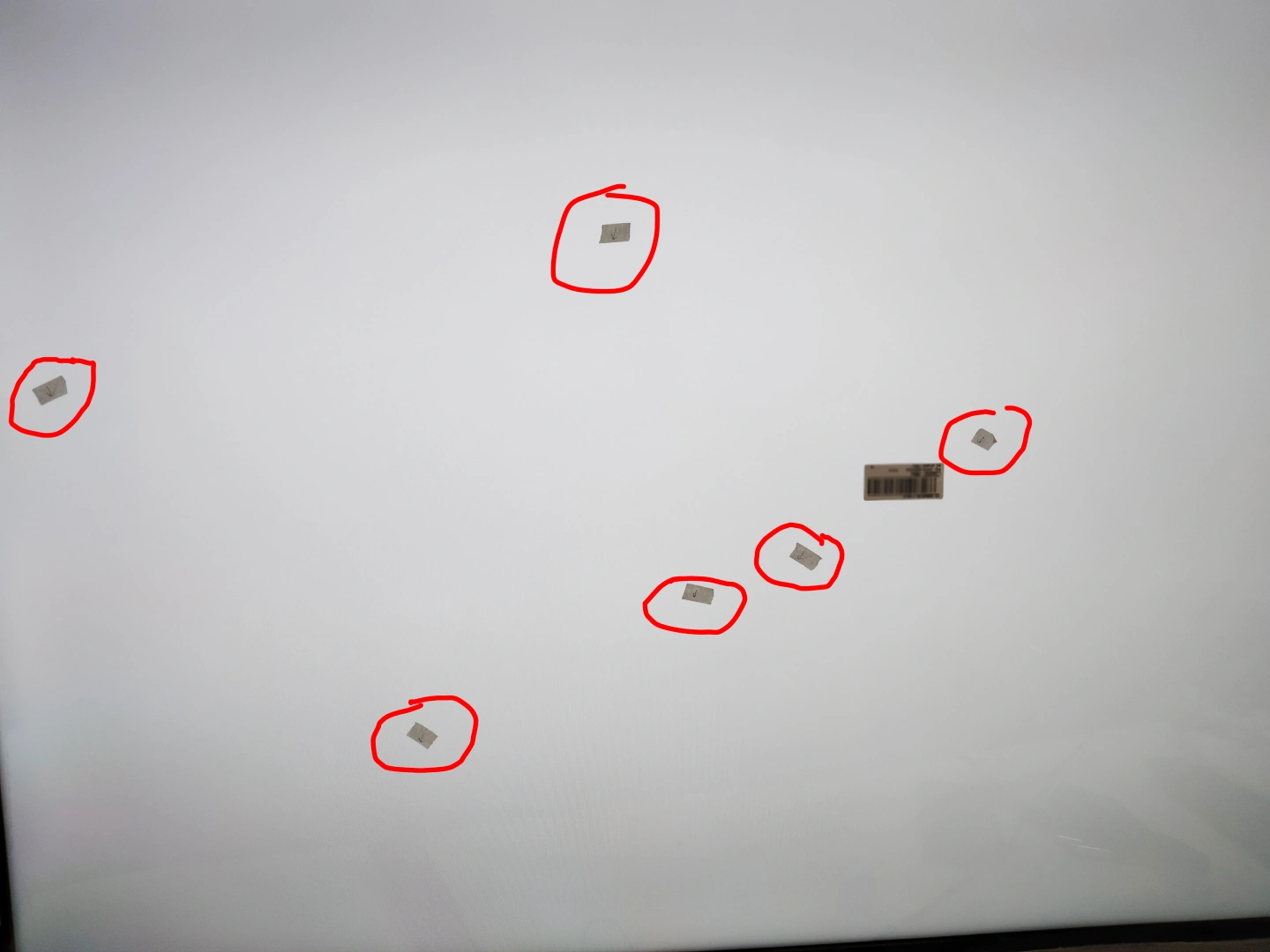

| Dots Defect⭐ | Bright dot, dark dots, adjacent dot in display |

| Scratch or dent on polarizer | Polarizer is damaged on the surface |

| Foreign Material | Foreign material(dust) in display |

| Polarizer bubble | Polarizer bubble in display |

| Mura⭐ | Uniformity(color) in display |

Note: Dot defects and mura defects are both extensive topics in LCD quality evaluation. This article focuses primarily on dot defects, as they are more frequently referenced in industry discussions and commercial practice. In general trading, dot defect criteria are commonly used as a key factor in defining the grade of an LCD panel.

Type of Dot Defects in Panel Grading

1. Bright Dots Defects

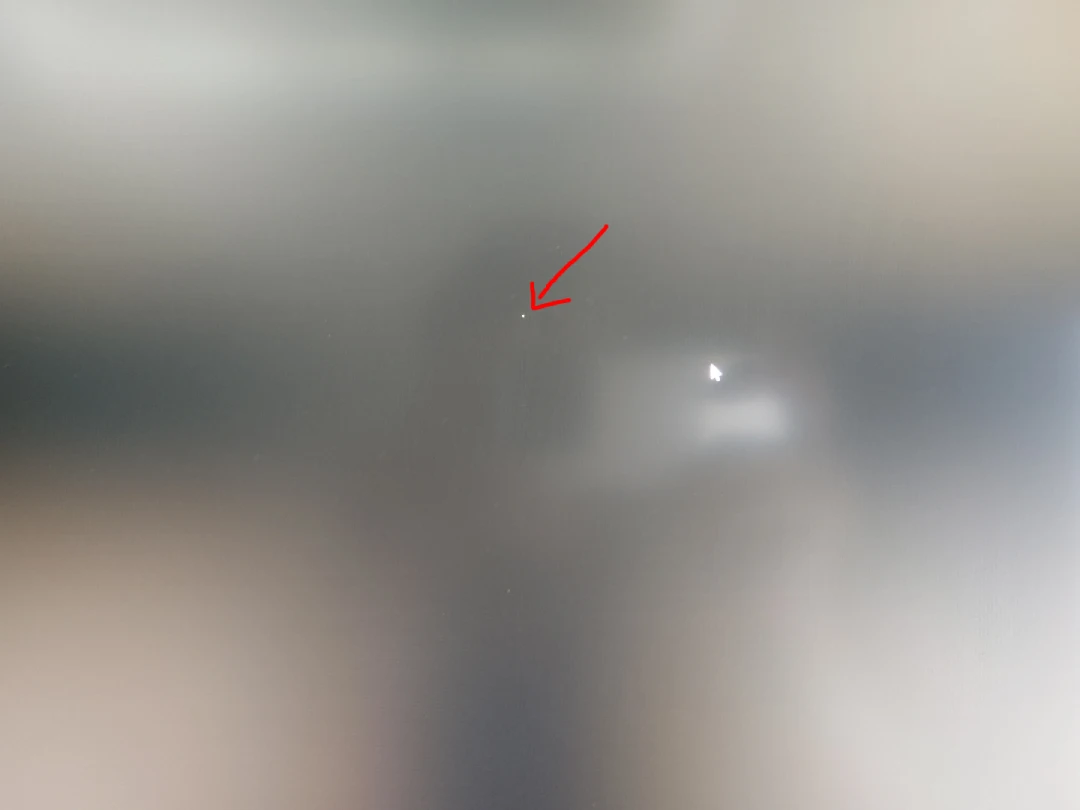

Bright Sub-pixel: Any sub-pixel that appears abnormally bright against a BLACK PATTERN or at L64 GRAY LEVEL PATTERN, detectable via visual inspection.

☆Black Pattern

Definition: Refers to the state where all pixels on the display receive a “0” luminance signal; theoretically, the screen should appear completely black.

Purpose: This is the most stringent environment for detecting Bright Dots.

Principle: Against a full black background, any sub-pixel that fails to close properly and remains illuminated will stand out like a star in the dark. Tiny bright dots observed in this mode are typically classified as Major Defects.

☆ L64 Gray Scale Pattern

Definition: A medium-low brightness gray screen. In the 8-bit display standard (256 gray levels, 0-255), “L64” represents a gray level at approximately 25% brightness.

Purpose: Used to detect abnormal dots or dark dots that are inconspicuous in Black Pattern but become visible at medium brightness levels.

Principle: * L0 represents pure black, while L255 represents pure white.

L64 falls within the dark gray tones. Certain sub-pixels may appear normal in pure black but exhibit uneven brightness, color shifts, or flickering when a small voltage is applied (entering the gray state).

2. Dark Dots Defects

Dark Dot Defect: Sub-pixels that appear as dark or inactive spots within the display area when viewing Red, Green, or Blue (RGB) color patterns.

★R,G,B Color Pattern

Definition: Refers to solid color patterns of the three primary colors: Red (R), Green (G), and Blue (B).

Purpose: Primarily used to detect Dark Dots (inactive sub-pixels) and color uniformity.

Principle: * Since each pixel is composed of R, G, and B sub-pixels, these patterns allow for the inspection of each individual sub-pixel’s functionality.

Red Pattern: Only red sub-pixels are illuminated while Green and Blue are turned off. If a black spot appears, it indicates a defective red sub-pixel.

Green/Blue Pattern: Similarly, these are used to identify defective green or blue sub-pixels.

Dot Defects(Minor) and LCD Panel Grade

In LCD panel grading, dot defects are one of the primary factors used to determine panel grade. Among dot defects, bright dot defects and dark dot defects are both evaluated, but bright dot defects are generally subject to stricter acceptance criteria due to their higher visibility in normal viewing conditions.

According to commonly used panel supplier specifications such as those from BOE, tolerance limits for bright sub pixel defects are typically lower than those for dark sub pixel defects. For example, under A− grade criteria, the allowable number of bright sub pixel defects is usually limited to fewer than five, while the allowable number of dark sub pixel defects may be higher, often fewer than ten. These thresholds illustrate how different types of dot defects are weighted differently in panel grade classification.

The following information is summarized from the documents titled “Visual Inspection Criteria for All Customers (32 inch Open Cell Q Grade)” and “Visual Inspection Criteria for All Customers (32 inch Open Cell A Grade)” specifications. It presents selected grading criteria related to dot defects, compiled for reference to help explain how LCD panel grades are determined in practice.

Visual Inspection Criteria (Partial) | |||

|---|---|---|---|

| Items | Details | A Grade | A- (Q) Grade |

| Sub Pixel Defects | Bright Sub Pixel Defect | ≤ 0 | ≤ 5 |

| Dark Sub Pixel Defect | ≤ 7 | ≤ 10 | |

| Bright and Dark Sub Pixel Defect | ≤ 7 | ≤ 12 | |

| 2 Adjacent Bright Sub Pixel Defect | 0 | ≤ 2 | |

| 2 Adjacent Dark Sub Pixel Defect | ≤ 2 | ≤ 3 | |

| 3 Adjacent Bright Sub Pixel Defect | 0 | ≤ 1 | |

| 3 Adjacent Dark Sub Pixel Defect | 0 | ≤ 2 | |

Although the table above appears highly technical and well defined, in real commercial practice it is not always treated as an absolute standard from the perspective of TV manufacturers and B2B customers.

In the LCD industry, dot defect criteria may vary between different panel brands. Even within the same brand, the acceptance limits can differ depending on panel size, resolution, or product positioning. As a result, visual inspection standards are often applied with a certain degree of flexibility during actual transactions.

In the following section, we will introduce a commonly used industry concept that helps both manufacturers and buyers better understand how LCD panel grades are evaluated in real world trading scenarios.

NBD(No Bright Dot) in LCD Panel Trading

Because there is no widely adopted global standard for LCD panel grading, the industry often relies on practical and simplified concepts to avoid unnecessary disputes during transactions. One such concept commonly used in the TV manufacturing field is NBD No Bright Dot.

In practice, NBD is used as a quick rule to distinguish whether a panel falls into A minus grade. If a panel contains any visible bright dot, it is typically classified as A minus. Conversely, a panel with no bright dot is generally regarded as A grade or above. An A grade panel may still allow a limited number of dark dot defects, which are less noticeable under normal viewing conditions. A plus grade represents a near perfect panel, where no bright or dark dot defects are visible to the naked eye.

This concept is widely applied in commercial negotiations. For example, when a customer requests an order with eighty percent NBD panels, it means that eighty percent of the shipment must meet A grade or higher standards with no bright dot defects, while the remaining twenty percent is generally accepted as A minus panels that may contain bright dot defects.

| Order Requirement | Panel Grade | Bright Dot Allowed | Shipment Ratio |

|---|---|---|---|

| 80% NBD | A Grade or Above | No | 80% |

| A- Grade | Yes | 20% |

How to Ensure A+ Grade Panels in TV Production

In TV manufacturing, achieving an A+ grade panel requires careful quality control at every stage. From a factory perspective, when we receive an order specifying A+ grade screens, we assign dedicated inspection personnel to test each panel individually. Only panels that meet strict A+ criteria—including no bright or dark dot defects visible to the naked eye—are approved for further assembly. These fully inspected and verified panels are then sent to the production line for TV assembly, ensuring that the final product meets the highest visual quality standards.

This approach highlights the importance of rigorous pre-assembly inspection, as A+ panels represent the top tier of display quality and require consistent handling to maintain their grade throughout manufacturing.

Conclusion

Understanding LCD panel grades is essential for both manufacturers and B2B customers when specifying or purchasing panels. Major defects define panels that are functionally unacceptable, while minor defects—especially dot defects—play a key role in distinguishing A−, A, and A+ grades. Concepts like NBD (No Bright Dot) provide practical benchmarks for evaluating panel quality in trading and commercial agreements.

By clearly defining and inspecting panels according to these criteria, factories can ensure that only compliant panels reach assembly, and customers can make informed purchasing decisions based on agreed quality standards. This systematic approach helps minimize disputes, streamline production, and maintain high visual quality across TV and monitor products.

FAQ

1. What determines the LCD panel grade for a TV or monitor?

LCD panel grade is primarily determined by the number and type of pixel defects, including bright and dark sub-pixels. Major defects that affect functionality disqualify a panel from standard grading, while minor defects like dot defects are used to differentiate between A−, A, and A+ grades. Additional factors, such as COF bonding quality and driver board performance, also influence the overall visual quality.

2. What does NBD (No Bright Dot) mean and why is it important?

NBD is an industry concept used to quickly identify panels that meet high-quality standards. A panel with no visible bright dot defects is considered A grade or above, whereas any visible bright dot typically classifies the panel as A−. NBD is widely used in B2B trading to set clear quality expectations, for example, specifying that 80% of a shipment must be NBD panels ensures consistent top-tier quality.

3. How do factories ensure panels meet A+ grade standards?

For A+ grade orders, factories assign dedicated inspection personnel to test each panel individually. Only panels with no visible bright or dark dot defects are approved for assembly. Strict control over COF bonding, driver boards, and overall workmanship ensures that the highest visual quality is maintained throughout manufacturing.

4. Can minor defects like dot defects affect the performance of the TV?

Minor defects, such as a limited number of bright or dark sub-pixels, generally do not affect the functional performance of the TV. They are primarily visual and affect perceived quality. However, the number and location of these defects are critical for panel grading, which impacts the final product classification and pricing in commercial transactions.

5. Are LCD panel grading standards the same across all brands and sizes?

No, there is no single global standard. Different brands may have varying tolerance levels for dot defects, and even panels from the same brand may have different standards depending on size, resolution, and product positioning. B2B customers and manufacturers often rely on practical benchmarks like NBD to establish a common understanding for trading and quality control.

Considering selling your own brand of TVs?

Upload your LOGO, we design and provide a set of images(TV bezel, TV boot screen, color box) to your email.(100% Free)